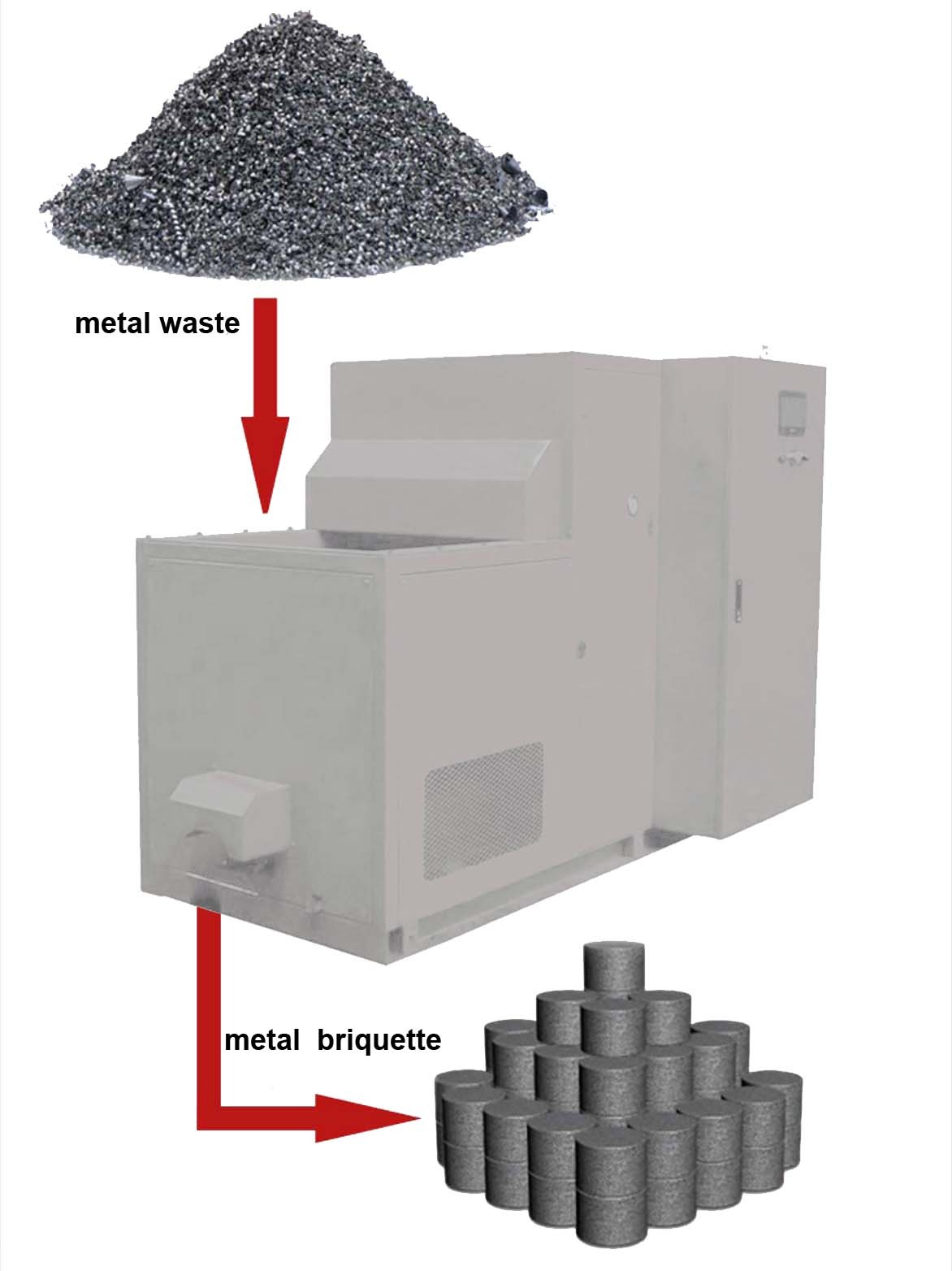

High efficiency metal waste hydraulic briquetting press machine

Detail Information

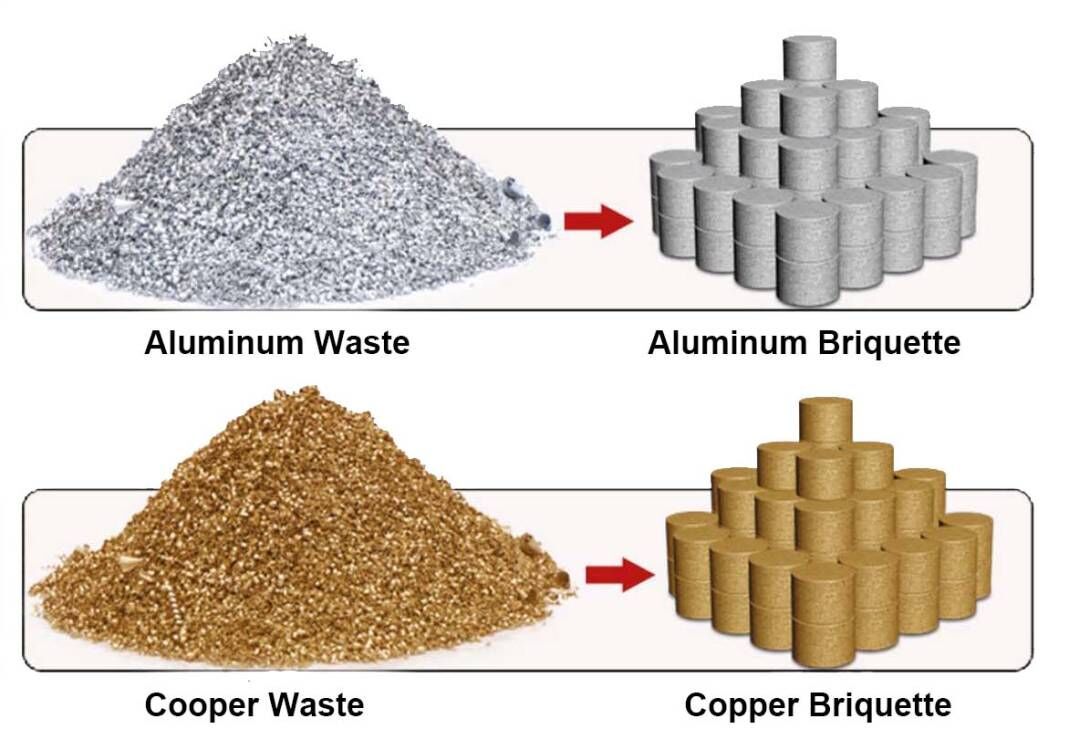

SUPU SPB100T Metal briquettes offer numerous advantages: Optimized storage and more efficient transport through volume reduction as well as cost-effective further processing. The briquetting process for metals also enables the recovery of expensive cooling lubricants, residual oils and emulsions, which are then fed back into the cooling or lubrication circuit. The resulting metal briquettes can be melted down directly, whereby they sink down in the melting process and thus melt with less slag formation and burn-off. The equipment also solves the footprint of the plant for stacking metal debris, saving the maximum use of space up to 40:1.

Advantages:

1. Direct and efficient melting down of the metal briquettes with significantly less burn-up

2. Volume reduction of up to 90% of the starting material

3. High pressing pressure for high briquette density

4. Better residue handling

5. Minimized disposal costs

6. Reduction of transport and storage costs

7. User-friendly design

8. High ease of maintenance

Technical Date:

|

Model

|

SPB100T

|

SPB130T

|

SPB130T Plus

|

|

Hydraulic briquetting

press power |

100 Ton

|

130 Ton

|

130 Ton

|

|

Briquette size

|

D75 * H50-70mm

|

D109 * H50-70 mm

|

D109 * H50-70 mm

|

|

|

Iron,steel: 1.27 KG/EA

|

Iron,steel: 2.73 KG/EA

|

Iron,steel: 2.73 KG/EA

|

Copper:1.53 KG/EA | Copper: 3.3 KG/EA | Copper: 3.3 KG/EA | |

Aluminum: 0.5 KG/EA | Aluminum:1 KG/EA | Aluminum: 1KG/EA | |

(Per Hour) | Iron,steel 120 KG/HR | Iron,steel 393 KG/HR | Iron,steel 1400 KG/HR |

Copper 150 KG/HR | Copper 475 KG/HR | Copper 1800 KG/HR | |

Aluminum 90 KG/HR | Aluminum 144 KG/HR | Aluminum 300 -500 KG/HR | |

Iron,steel 4.8 g/cm³ | Iron,steel 4.8 g/cm³ | Iron,steel 4.8 g/cm³ | |

Copper 5.8 g/cm³ | Copper 5.8 g/cm³ | Copper 5.8 g/cm³ | |

Aluminum 1.9 g/cm³ | Aluminum 1.9 g/cm³ | Aluminum 1.9 g/cm³ | |

Main motor power | 7.5 KW / 380V | 11 KW / 380V | 22 KW / 380V |

Briquetting period | 25 -30 sec | 25 -30 sec | 11 -18 sec |

Discharge bin capacity | 220 L | 220 L | 650 L |

Hydraulic oil volume | 360 L | 360 L | 400 L |

Machine size | L2155*W1410*H1950mm | L2155*W1410*H1950mm | L2275*W1265*2H235mm |

Machine weight | 3000 KG | 3000 KG | 3000 KG |

Available for paper,document and confidential paper shredding and briquetting solution

Solution for shredding,crushing and briquetting combination equipment and recycling line

Please send your message to us

- Mobile Phone

- *Title

- *Content